| Parameter | Unit |

| Table diameter | mm |

| Max swing diameter | mm |

| Max turning diameter | mm |

| Turning height | mm |

| Working table load | kg |

| Spindle motor type | |

| Spindle speed range | rpm |

| X axis travel | mm |

| Z axis travel | mm |

| Controller | |

| Hydraulic / coolant tank capacity | L |

| Machine dimensions (LxWxH) | m |

YV-1000 Ø 1000 Ø 1350 Ø 1100 900 4000 30/37 2-600 1120 800 Fanuc 0i-T 65 / 400 3.8x4.4x4.6

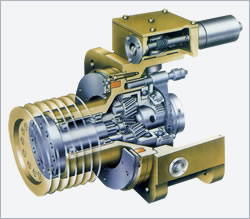

HIGH PRECISION SPINDLE

ZF gearbox

-Eliminates noise and heat transmission to spindle assembly.

-Eliminates vibration transmitted to the spindle.

-Separate lubrification systems for spindle and gearbox eliminate heat transmission.

-High transmitted efficiency ( over 95%)

-Gear shift is controlled by integrated shift system

FANUC motor

The machines are fitted with a powerful high performance FANUC spindle motor and German ZF dual speed gearbox with high torque output. this allows the machine to be used under heavy cutting conditions and meets the application for all kinds of cutting operations covered by vertical turning lathes.

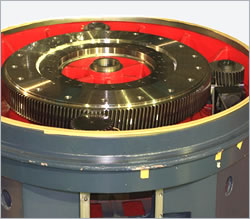

The large vertical turning lathes are fitted with crossed roller bearing, featuring high precision, high loading and high rigidity design is achieved during manufacturing large and non-symmetric work pieces.

- Two rows of rollers in the space of one

- Saves space and lower the machine base height for easy operation.

- Low centre of gravity in the machine and low centrifugal forces

- Nylon separators feature low inertia, ensuring the machine operation under low running torque.

- Heat dispersion and wear-resistant for longer bearing life

- Provides high rigidity, high precision, shock-resistant and ease of lubrication.

ADVANCED RAM DESIGN

X axis is wide span box way design with Turcite-B and forced lubrication system to reduce friction and wear in order to maintain high accuracy and stable machine performance.

The crossrail is movable to suit the work piece height, the movement is obtained by lead screws via a reduced motor, the crossrail is hydraulically clamped by 4 powerful hydraulic cylinders after positioning.

The symmetric box type design cross rail has heat treated slideways, the pre-tensioned ballscrew is fitted to integrated bearing support blocks, this proven design gives total satisfaction and ensures a superb high level of accuracy.

The cross-rail can be moved up and down independently and is an ergonomic operation design feature. Four super high pressure cylinders clamp and hold the cross-rail automatically and maintain precision after its positioning.

AUTOMATIC TOOL CHANGER SISTEM

Chain type Tool Magazine

Chain type tool magazines are driven by a servo motor for fast positioning of the ATC, multi choice capacities options are available, such as 32, 48, 60... tools capacity.

Integral and Safe Design

Full enclosure guarding of tool magazine protects the tool taper, easy and convenient for cleaning. A door interlock is used conforming to the strict CE regulations.

A type Turret

Turret positioning is achieved with high accuracy curved coupling, providing positioning accuracy of 5” and repeatability 3”. Turrets with curved coupling withstands heavy cutting forces, a high torque hydraulic motor ensures rotation. The speed of turret rotation and tool change is smoothly controlled by a cam system. The PLC ensures the shortest route and bi-directional tool selection reducing the tool change time.

High efficient transmission

Heavy cutting depends on the power of the main spindle motor. The machines are equipped with high specification Fanuc spindle motors and German ZF dual speed gearboxes with high torque output. This allows the machine to be used under heavy cutting conditions and meets the application for all kind of cutting operations covered by vertical turning lathes.

Box slideways structure

The casting of X axis box slideways are heat treated and stress relieved, this design gives the best rigidity to ensure heavy duty cutting. The slideways lubrications is controlled by an automatic central lube feeding system. The volume and timing of lubrications is controlled by CNC and enhances the machine accuracy & life. The X and Z axes box guide ways are induction hardened and precision ground, the matting sliding faces are Turcite B coated allowing slide assemblies to move with ease and low friction.

Automat Tool Changer (ATC) system

Design of the 16 tool magazine meets the demands of various machining operation and is convenient for fast tool selection and easy operation. Maximum weight of the tool holder is 50 kg. Maximum loading weight of tool magazine is 360 kg. Full guarding of tool magazine protects the operator whist allowing easy access for cleaning.

High precision bearings

The large vertical turning lathes are equipped with cross roller bearing. The bearing, with the characteristics of high precision, high loading and high rigidity, is suitable for machining large and non-symmetrical work-pieces.

High efficiency transmission

High grade nickel-chrome alloy steel is used for the driven gear. Correct heat treatment and accurate grinding allows it be classified as first class precision in the Japanese JIS 1 standards.

X axis and z axes

X axis and Z axes are driven directly by AC servo motors ensuring high rigidity & accuracy. The X-axis & Z-axis are equipped with a flexible high accuracy alignment system this absorbs the loading during abnormal operation. Heavy damage will be reduced during a crash situation. This design also allows for easy maintenance

Cross rail moving system

The cross-rail can be moved up an down independently and is an ergonomic operation design feature. Four super high pressure cylinders clamp and hold the cross-rail automatically and maintain precision after its positioning.

BEST COMPLEX TURNING AND MACHINING SOLUTIONS

High precision CF axis gearbox delivers precise positioning accuracy, coupled with the functions of a machining centre that allows for a wide range of work to be carried out in one set up, so reduces investment costs & machining costs.

The live spindle motor (ATC+C series), coupled with the dual speed gearbox is located on top of the RAM, driving the live spindle via drive shaft. The use of dual speed gearbox on the live spindle enables high torque output for face milling, end milling, drilling, and tapping capacity.

The You Ji series of vertical turning lathes are designed especially for high precision, high rigidity, high stability, under super heavy cutting conditions including non-symmetric work-pieces | |

| |

|

The outstanding rigidity of the structure and design provides mechanical features for super heavy cutting, which achieves maximum machining accuracy and stability thus increasing the life of cutting tools. The machine column and base are made of high grade cast iron and heat treated with a stress releasing process to ensure static rigidity and dynamic accuracy under perfect conditions. |

|

|

The heavy box section structure of the column provides maximum support for the sliding crossrail during heavy cutting conditions. The highest degree of machining precision will be maintained during heavy uninterrupted cutting operations. |